|

|

|

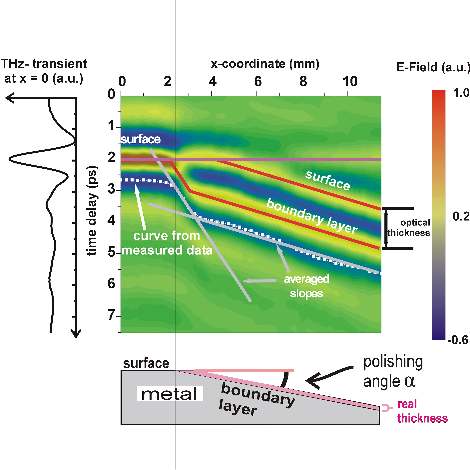

In contrast to typical optical wavelengths many commercial materials like paper, plastics or ceramics are transparent in the THz regime. Therefore THz spectroscopy is also a powerful tool to perform spatially resolved analytic. Principally there are two ways, the two dimensional analysis of transmitted THz radiation (Imaging) and the three dimensional (depth resolved) analysis of reflected THz pulses (Tomography). As an example of the capabilities in By the time delay detection of a THz pulse reflected from the surface or any inner boundary layer within the sample its reflex origin can be determined. To calculate the thickness of each layer it is however needed to know the refractive indexes and thereby the propagation velocities of the THz pulse in the respective materials. These refractive indexes can be detected in a sample with a known geometry, which can be received by polishing it in a small angle. Such a measurement is shown in fig. 2. The various reflexes from the surface and boundary between the ceramic layer and the metal substrate can be easily seen. This figure gives a good impression how THz tomography enables to look inside of a sample. With the knowledge of the refraction indexes of the respective layers it is now possible to determine their thicknesses.

More information on this work:

|

|

[Martin Brucherseifer] [About me] [Resume] [SEM / FIB] [Scanning Probe Microscopy] [THz Spectroscopy] [DNA Analysis] [THz Modulation] [THz Tomography] [Optical Pump - THz Probe] [AIXScan] [Publications] [Links] [Disclaimer] |

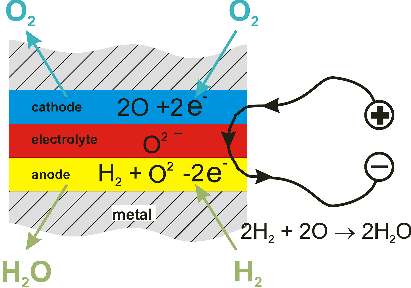

a tomography setup the analysis of a multilayer ceramic sample used for Solid Oxide Fuel Cells (SOFC) is demonstrated here. These fuel cells have a great potential for power generation applications. However, there is no nondestructive system established to date for quality control and optimizing the sensitive manufacturing process.

a tomography setup the analysis of a multilayer ceramic sample used for Solid Oxide Fuel Cells (SOFC) is demonstrated here. These fuel cells have a great potential for power generation applications. However, there is no nondestructive system established to date for quality control and optimizing the sensitive manufacturing process.